For nearly 40 years, GMI has been supporting manufacturers in the implementation of their projects.

With an extensive understanding of all of the business value chains by field of activity, GMI is experienced in project management.

GMI offers genuine active collaboration by area of expertise. From defining to formalising specification, to the delivery of the manufactured items in strict compliance with the agreed delivery schedule.

Industrial know-how and technical expertise enable GMI to adapt to many activity sectors and to offer relevant, viable solutions.

Our skills

at a glance

Listening/Analysis

Specifications

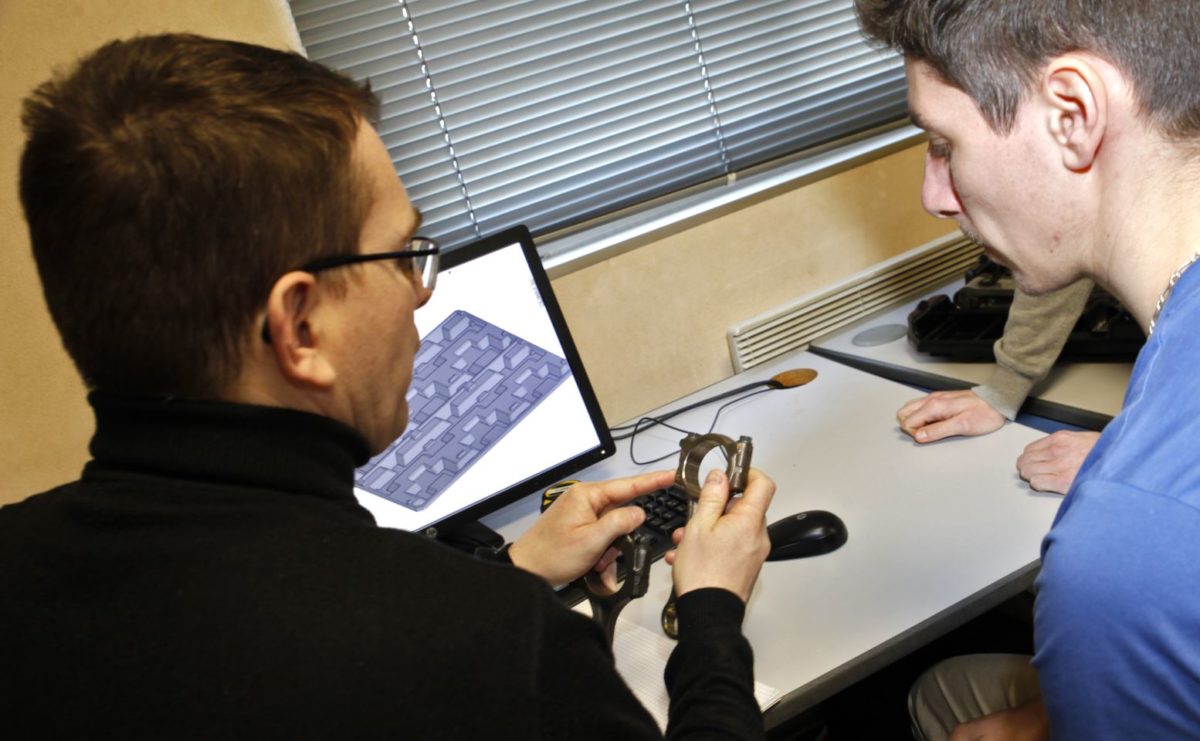

Research and design

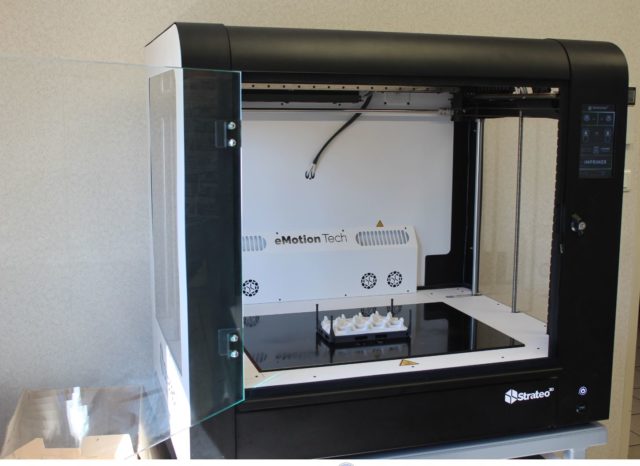

Prototyping

Test / Simulation

Tools

Industrialisation

Industrialisation

GMI’s industrialisation division (method consultancy, start groups, project managers) design and implements the series resources that ensure qualitative, repetitive production.

Initial sampling and customer acceptance form a key stage on starting a project, enabling both parties to ensure product conformity and compliance with specifications.

Industrial R&D and innovation

GMI’s Research and Development department actively monitors technological developments and analyses new market expectations to provide innovative solutions to tomorrow’s problems. From the environment to new technologies, our engineers anticipate and develop new processes, principles and materials to ensure that we remain a major future-oriented player.