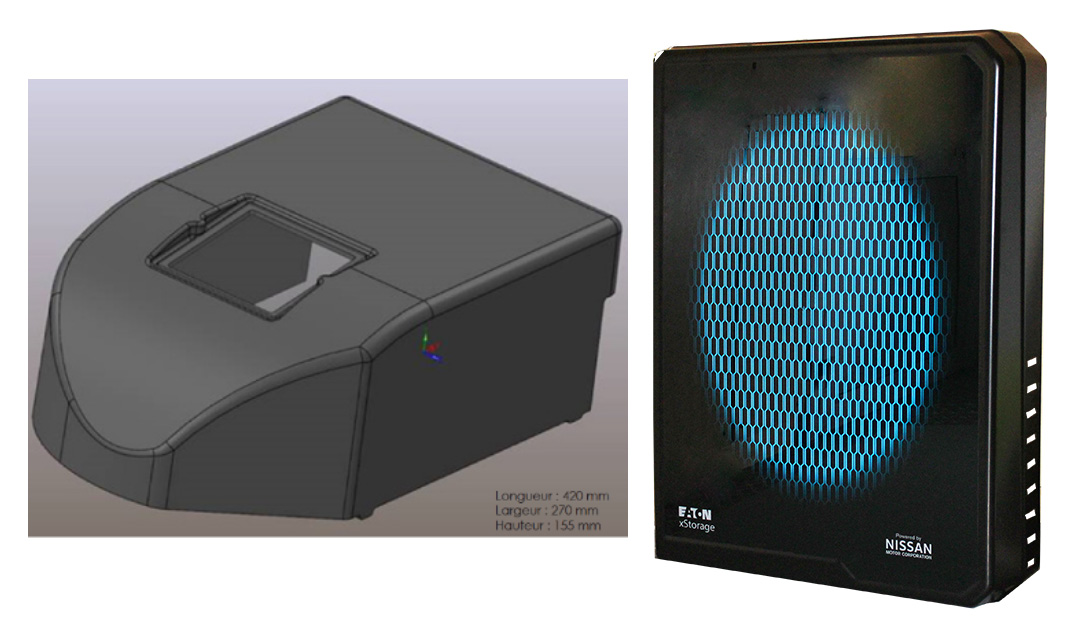

GMI designs and manufactures bespoke protective covers, fairings, cladding and parts.

Our design office and unique know-how is available to support you. Mobilised around your project, our teams can advise you in your choice of materials and technologies to ensure your complete satisfaction with your functional and/or aesthetic parts.

Our engineers and multidisciplinary technicians design and produce your projects in compliance with industrialisation, environmental and cost constraints.

Our production process incorporates the various workshops required for the production of the finished products (processing, profiling, machining, assembly, assembly of accessories, finishing, quality control, packaging and shipping).

Our skills at a

glance

Research and design

Thermoforming / Rotomoulding

Modelling, prototyping, 3D printing Profiling

Machining on 5 axes

Painting / Marking / Screen-printing

Ultrasonic welding

Assembly