In a very competitive market, car manufacturers and tier 1 and tier 2 suppliers must be able to depend on reliable partners. For nearly 40 years, the GROUPE MAILLARD INDUSTRIE has been meeting the strictest requirements and supporting all its customers looking for performance, from consultancy through to serial production.

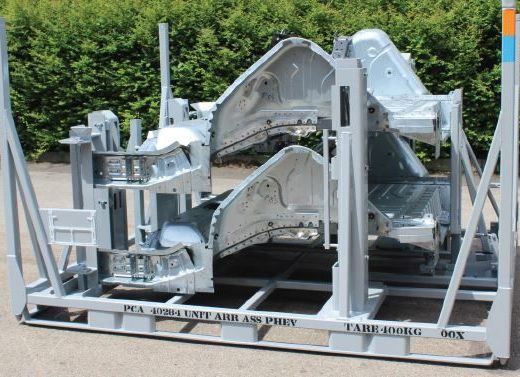

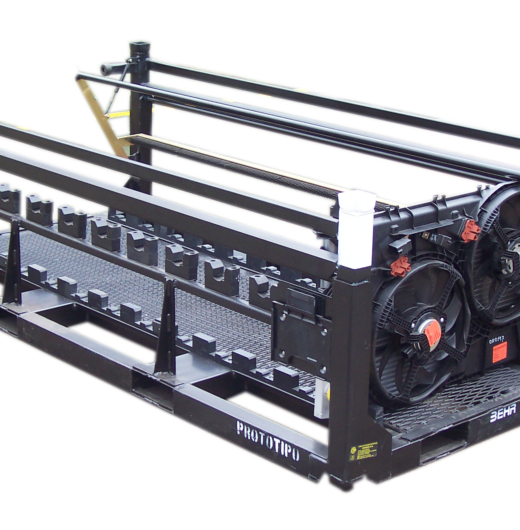

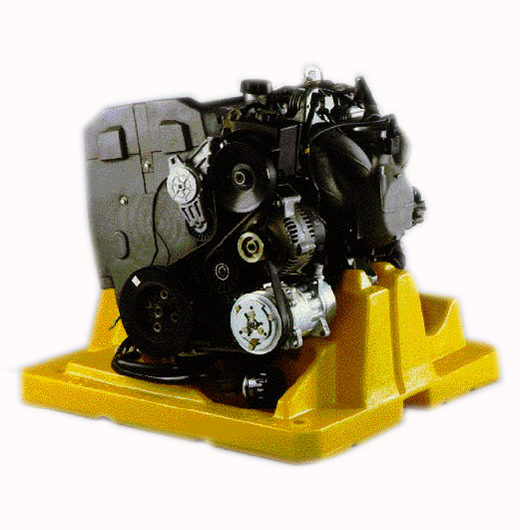

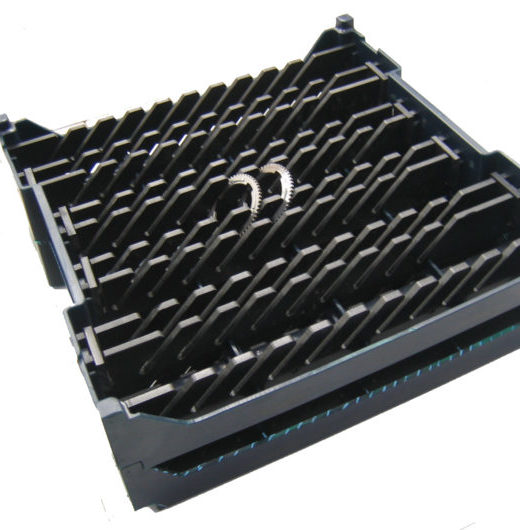

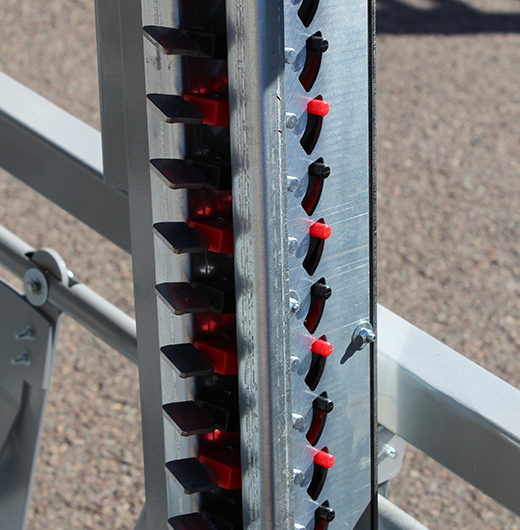

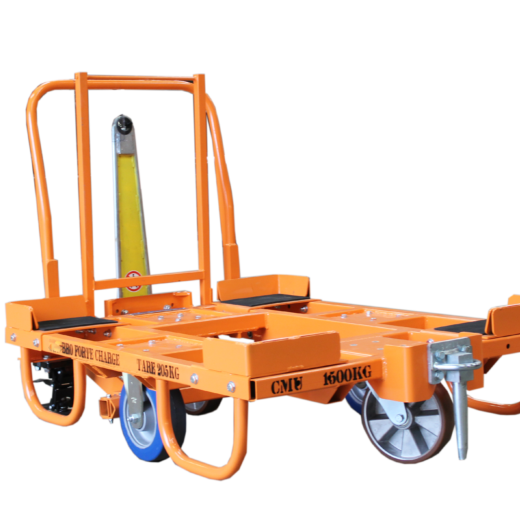

Thanks to its experience in the complementary professions of metallurgy and plastics processing and its extensive knowledge of automotive supply chain organisation, GMI provides specific and innovative solutions to meet every challenge: environmental impact, parts quality, personnel safety, ergonomics, fatigue, automation, synchronous supply… GMI designs and manufactures specific containers, sustainable packaging, logistics rolling stock and supply furniture that are cost-effective and adapted to the packaging of all the components of a vehicle.

GMI will meet your expectations whilst putting innovation and environmental protection at the heart of its solutions.

GMI provides support in the partial or complete management of all your projects in France or overseas for the ongoing optimisation of logistics flows, ranging from the layout of work stations to supply chain management.

Valued by key players in the automotive industry, the group’s multicultural teams are present in each country to support you in the management of your international projects.

Our skills at a

glance

Consultancy and expertise

Project management

in France and internationally

Research and

development Delegated engineering

Extensive experience in

Plastics processing and metallurgy

Installation, maintenance

on-site training

1

Specifications, data approval

2

CAD Research and Development, Industrialisation

3

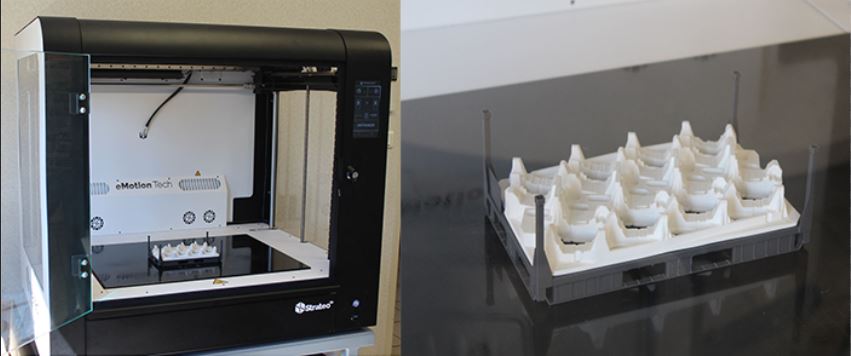

Prototyping, 3D Printing, Test & Simulation

4

Approval / Certification

5

Industrialisation, Tooling, Preseries / Series production

6

Quality control / Delivery

Delegated / simultaneous engineering

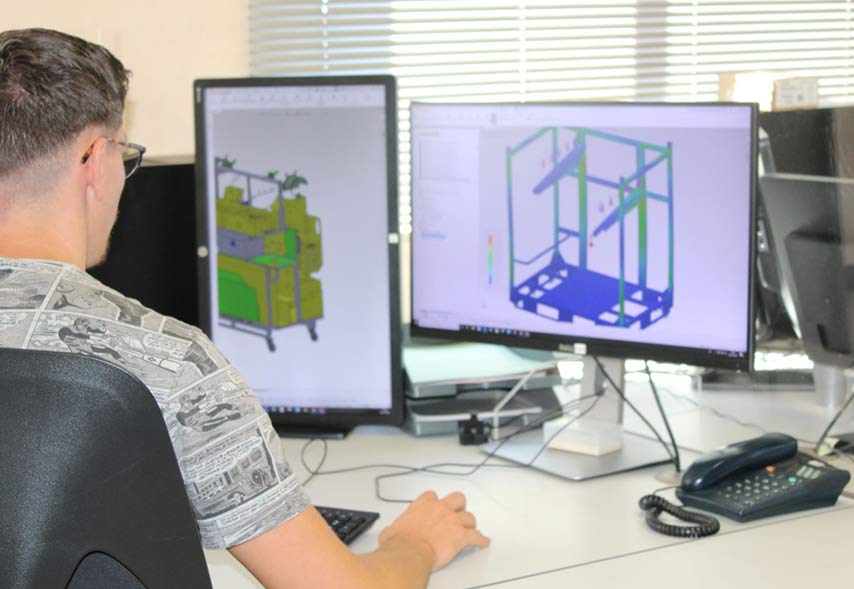

To meet a growing demand due to the reduction of design and marketing times for new vehicles, several years ago we introduced a structure that allows us to handle business using Delegated engineering services.

From analysis of your requirements to the implementation of complete solutions, our teams oversee the management of you project. We work closely with your teams to ensure the development, planning and validation of the selected solutions, by controlling quality and by optimising costs and deadlines.

Multidisciplinary design office

Our design office meets the multiple requirements for adapting packaging to transport, workstations and automated lines.

Every day our engineers and designers develop comprehensive optimised solutions to satisfy the technical, ergonomic, mechanical and environmental constraints and specificities of each project.

- Volume optimisation / Bulk / Mass / Foldability

- Hygiene and security legislation

- Aesthetic part Quantity

- per pack

- Recycling requirements

- Transport type / Logistics flow

- Identification

- Ergonomics

- Carbon footprint reduction Manual

- robotised handling

- Storage

- …

R&D department

Our R&D engineers constantly analyse new expectations and develop innovative solutions to tomorrow’s problems. They research and/or develop new materials and improve our production systems so that we are armed with the answers before you have asked the question.

Prototyping and tooling

Our factory has a dedicated workshop and the industrial equipment needed to create prototypes for the validation of technical solutions (geometry, dimensional, ergonomics, kinematic…) before launching serial production. 3D printing of the part to be packaged for physical validation of the prototype completes the service.

The design and creation of tools and templates is overseen by our team of specialists and are subject to geometric, dimensional and functional validation to ensure quality and repeatability of productions.

Production

With our extensive experience of complementary technologies (welding / thermoforming / rotomoulding / polyurethane / wire forming) and our expertise in each field, we are able to optimise each stage of the production process in order to guarantee optimised technico-economic solutions.

Certified ISO 9001 compliant since 1996, our production patterns supported by our processes allow us to guarantee product quality at each stage of production.