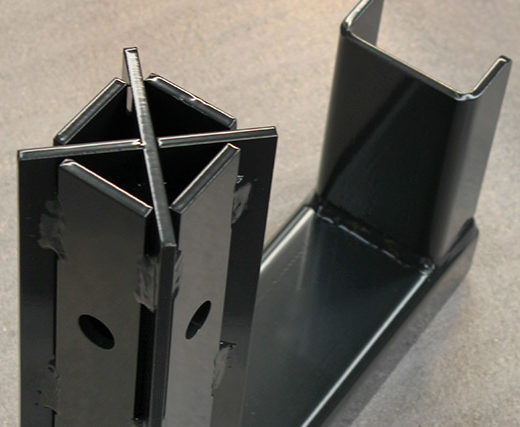

Steel – Aluminium – Stainless steel

Recognised for 40 years for its extensive expertise in metallurgy, GMI and its subsidiary ITS design and manufacture welded simple or complex structures in a range of sizes for all areas of activity both in France and internationally.

Much more than just a sub-contractor, GMI will support you throughout the design phase, prototyping and serial production of complete or partial sub-assemblies.

The organisation and the equipment of the welding division mean that we are able to offer comprehensive service at a fair price: laser cutting, folding, bending, welding, blasting, painting and assembly.

By integrating all of these workshops, GMI delivers real savings in cost, time and quality.

Our skills at a

glance

Design offices

Laser cutting

(tube and sheet)

Cutting / Folding / Bending

MIG/MAG and TIG robotised and

manual welding

Finishing / painting

Assembly

The equipment allows the shaping of tubes or sheets and meets a wide range of manufacturing requirements for metal parts and finished or semi-finished assemblies. Our experience in welding ensures quality and productivity.

Main industrial equipment

Shearers: cutting width 3000 mm, up to 12 mm

Press brake: Apron length 4000 mm

Punching Machine: Up to 12 mm, width 120 mm

Band saws: 6000 mm length, max. square profile 300x 100 mm, max. diameter 180 mm

Welding

Our welding expertise fulfils all steel, stainless steel and aluminium requirements.

In order to meet the needs of medium and large series manufacturing competitively, we have a high-capacity welding plant equipped with semi-automatic and robotic stations.

Main industrial equipment

— MIG MAG

— TIG

— pulsed welding

— tilting robots

— 2-axes linear robots

— modular plates

Completion – Finishing

We are equipped to offer aesthetic finishes and technical coatings on all your projects, in particular paint and marking finishes, stainless steel polishing, anti-corrosion treatment…

For your aesthetic parts, we have an automated polyester epoxy powder paint line and a liquid paint booth.

Main industrial equipment

— Polyester epoxy powder paint line: 32 cradles – 2000 x 2000 x 3000 mm

— Large dimension liquid paint booth: 7000 x 3000 x 3000 mm

— Blasting centre: 2000 x 2000 x 2000 mm

Assembly – Logistics

We carry out assembly operations in a dedicated workshop to deliver finished assemblies to our customers.

Main assemblies

— Off-plan assembly: frame elements, mechanical elements, various accessories (screwing, drilling, fitting inserts, riveting, bolting…)

— Positioning of elements: springs, hinges, wheels, casters, locks, mechanical elements (bearings, pins, axles)