Groupe Maillard Industrie (GMI) has always been in constant research for optimizing its production processes. The company, precursor in its technologic choices, has naturally turned to connected, robotized and intelligent means of production.

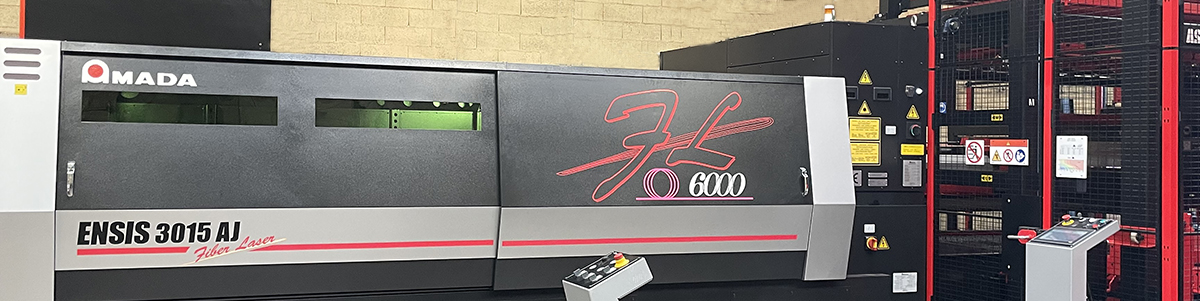

For its welding activity, GMI has just equipped itself with a brand new fiber-optic laser cutting installation: an Amada Ensis 3015. Equipped with the latest digital technologies, this imposing unit, 19 m long and 6 m high, is fully automatic. In fact, it has an autonomy capacity of 20 hours.

The loading of the raw material (steel, stainless steel and aluminum) and the unloading of the finished parts are carried out by fully automated lines.

The cutting performance and speed are equally impressive. And the nitrogen cutting technology ensures the best quality and finish of the manufactured parts, including the prevention of material oxidation.

As with any machine of the Industry 4.0, the intuitive digital touch screen programming improve the comfort of use for the operators. In addition, the elimination of various repetitive tasks and manipulations allows a real enhancement in working conditions. Technology allows us to valorize the role of the human being, who is now at the center of the system.

This technological performance is perfectly in line with GMI’s commitment to sustainable development, energy transition and decarbonization of its activities.

In addition to increasing the company’s productivity by 30%, this ecological investment considerably improves the energy efficiency of its production. This new installation has reduced the energy consumption of GMI’s laser cutting activity by 70%.

When technological innovation goes hand with eco-responsibility and sustainable investment.

To view a video of the performances of this impressive machine :